The Greatest Guide To Soda Blasting Auckland

Table of ContentsFacts About Soda Blasting Auckland RevealedSee This Report about Soda Blasting AucklandGetting My Soda Blasting Auckland To WorkSome Ideas on Soda Blasting Auckland You Need To KnowFascination About Soda Blasting AucklandThe Facts About Soda Blasting Auckland Uncovered

Industrial cleaning with blowing up technology gets rid of material forcibly particulates on to a surface area under high pressures. Dry Soft drink blasting eliminates surface area grime without needing to clean as well as remove waste water or create further damages or spills. The most awful issue in blowing up is the presence of wetness in the system.

What Does Soda Blasting Auckland Do?

The very same amount of wet sand would strike the target with even more pressure, and wouldn't blow in the wind.

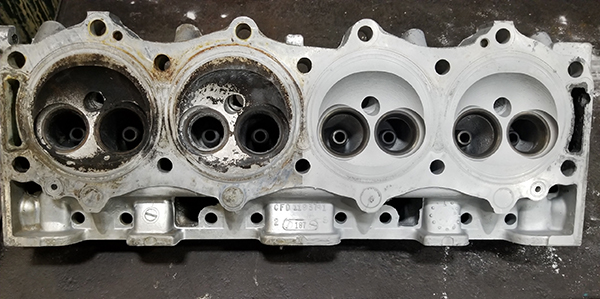

Blowing up with soft drink is still abrasive, but significantly extra mild than sandblasting, it won't cause damages to the surface that is being cleaned. A soda blast will utilize much less stress than typical sandblasting, and also blowing up soft drink media is so environmentally friendly that it has even been used to clean historic icons like the Statue of Liberty! The abrasive blasting power that is used with soda blasting can be used to remove paint, grease, mold, oil, or soot without harming the surface areas below, like glass, chrome, and even slim sheet steel.

Making use of a reduced stress however high volume blasting device, compressed air is sucked through carrying the salt bicarbonate with it. This works as a non-damaging unpleasant ideal for usage on a large range of surface areas. The sodium bicarbonate explodes as it hits the surface area, delicately raising as well as eliminating contaminants away as it does.

Soda Blasting Auckland Can Be Fun For Anyone

In the past, the only way you can eliminate paint or various other undesirable materials from a contaminated surface area, was to chip it off, sand it, use extreme chemicals or sand blast it. Now there is Sodium Bicarbonate BLASTING! Soda Blasting is a process that can strip almost any surface in an efficient and also safe way.

It likewise eliminates the translocation of oil and also oil. The safety of sodium bicarbonate to workers is well recognized, since it has remained in use for some 160 years. The bicarbonate barrier system is the significant added cellular buffer in the body, hence salt bicarbonate becomes part of the body's regular chemistry.

As a solid barrier for acids as well as antacid, soft drink removes acidic problems externally of the substratum. For conditions with high acidic degrees, acid rain or central heating boiler fly ash, blasting with soft drink will certainly reduce finish failings. As long as baking soft drink is on a ferrous steel surface area, rust will not form.

The Facts About Soda Blasting Auckland Uncovered

Most continue reading this of the times, totally free moisture combines with carbon dioxide in the ambience to develop carbonic acid. This acid launches a free metal (ferrous) ion which integrates with oxygen (oxidizes) to form corrosion. Soft drink barriers acids and also prevents the release of free metal ions and prevents corrosion. Soft drink blast media can be dissolved in fresh water.

treatment systems or open rivers, with proper discharge permits. Soda Blasting Auckland. Waste quantity is typically lowered to much less than 5% of the original waste quantity. With enhancing garbage dump costs and also obligations, this advantage comes to be more vital everyday. Typical grades of soft drink media (without any type of hard accumulations) do not profile steel. When an operator eliminates a finishing from a metal surface area, she or he subjects the existing support pattern under the finishing.

For projects where the finish is covered with grease, carbon, salt or other contaminants, the much more typical blasting techniques call for the covering to be content totally cleaned prior to blowing up. This is required to ensure that the impurities externally of the finishing not be driven via the covering and into the surface area of the substrate, triggering future finish failing (Soda Blasting Auckland).

Some Known Details About Soda Blasting Auckland

The procedure of Soda, Blasting was very first established in 1972, when engineers in the United States were trying to develop an approach of cleansing the Statuary of Freedom which would certainly not damage the surface and be environmentally friendly. From this procedure Soft drink blowing up was born as well as has since been used worldwide as a reliable eco pleasant cleaning process that services nearly any type of surface.

The ability to adjust stress in between such a big range allows one of the most persistent or delicate of materials to be cleansed. DK Soda, Blasting use one of the most reliable array of machinery on the market today, all our equipments have actually been particularly manufactured with the highest possible of requirements and are set up to utilize the best of Soda.

Far, soda blowing up sounds like an exceptionally effective way to eliminate contamination without destructive surfaces. Any type of why not try these out completely dry blowing up media creates dirt that drifts everywhere as well as obtains right into everything.

The Basic Principles Of Soda Blasting Auckland

In other instances, such as large, awkwardly designed jobs or tasks that can not be quickly relocated (a parking garage for instance), containment can be a time consuming as well as expensive step. No blowing up process can absolutely be dustless, but with vapor abrasive blowing up, the dust is lowered significantly contrasted to dry blasting.

The Graco Eco, Repartee 2 Vapor Abrasive Blast Solutions include a pump that pressurizes a pot of water and also media. As water is metered right into the pot, the media moves right into the blast circuit and with the pipe as well as nozzle throughout blowing up. The accurate control of the wetted media leads to significant dirt reduction without compromising efficiency.

47-0. 95 L) of water departures the nozzle per min.